Aluminium, the Modern Metal

One of the modern world’s more versatile materials, aluminium is used in everything from soda cans to airliners. Aluminium sheet can be molded, extruded, machined, cast, shaped and formed into such a variety of things. Aluminium is a wonder of modern metallurgical art. However, it was only during the 1880’s that a process was developed that made the widespread use of aluminium possible. Before the development of this process, aluminum as a metal was more valuable than gold in it’s pure form.

Elementally speaking, aluminium has an atomic weight of 13 and is a member of the boron group of chemical elements. In its metal form it has a melting point of 660 degrees centigrade. Aluminium is the most abundant metal in the earth’s crust. However, it never occurs as a metal in nature because it is chemically too reactive. Aluminium is found as a compound in over 270 different minerals. The chief of these minerals being bauxite.

The ancients used alum, which most modern sources refer to as alumina from which aluminium comes from. The scientist Wohler is generally credited with first isolating the metal in 1827. Alumina was used in the textile industry during the 1800’s as a mordant. Modern aluminium industry was born through the discovery of a process for separating purer forms of alumina.

“The ancients used alum, which most modern sources refer to as alumina from which aluminium comes from.”

The Bayer process has changed very little since it was first used in 1887 and is still the chief method for separating aluminium from bauxite. The bauxite is washed in a caustic solution which separates the alumina bearing ores from the oxides and other material in the bauxite. Through the use of heat, pressure, and chemical processes, the alumina bearing ore is extracted and purified. Ultimately the ore is refined into aluminium which is used in its metal form by much of the world.

Aluminium is not a strong metal but when alloyed with other metals, it develops very useful characteristics. The characteristics include corrosion resistance, lightweight, and tensile strength. Aluminium is also insoluble in alcohol though it is be soluble in water in certain chemical forms.

Aluminium is a better structural material than steel, because it has about a third of the density and stiffness of steel. Therefore, aluminium has replaced steel as the armor of choice for modern warships. It is also used as armor sheeting on many modern vehicles, due to it’s lightweight.

We are most familiar with aluminium as a metal. Its properties as a metal are highly desirable. It is corrosion resistant, nonmagnetic and non-sparking. When tempered and alloyed with the proper element, such as copper or manganese, it has enough tensile strength to be useful in many applications as a light yet durable structural material. Aluminium is also useful in the chemical industry, as an ingredient in explosives and other chemical processes. It retains its high reflectivity when powdered making it an important component in paints and coatings.

Aluminium Alloy

In our daily lives, aluminium is used extensively. The aerospace industry would be at a standstill without aluminium which makes up the material in most aircraft. The automotive industry also uses aluminium sheet in engines, car frames, wheels and other parts of the vehicles we drive. Aluminium sheet is used in our kitchens as pots, pans, aluminium foil and various cooking utensils. Aluminium sheet is also used in power transmission lines. Though not as conductive as copper it’s lightweight makes it ideal for power lines.

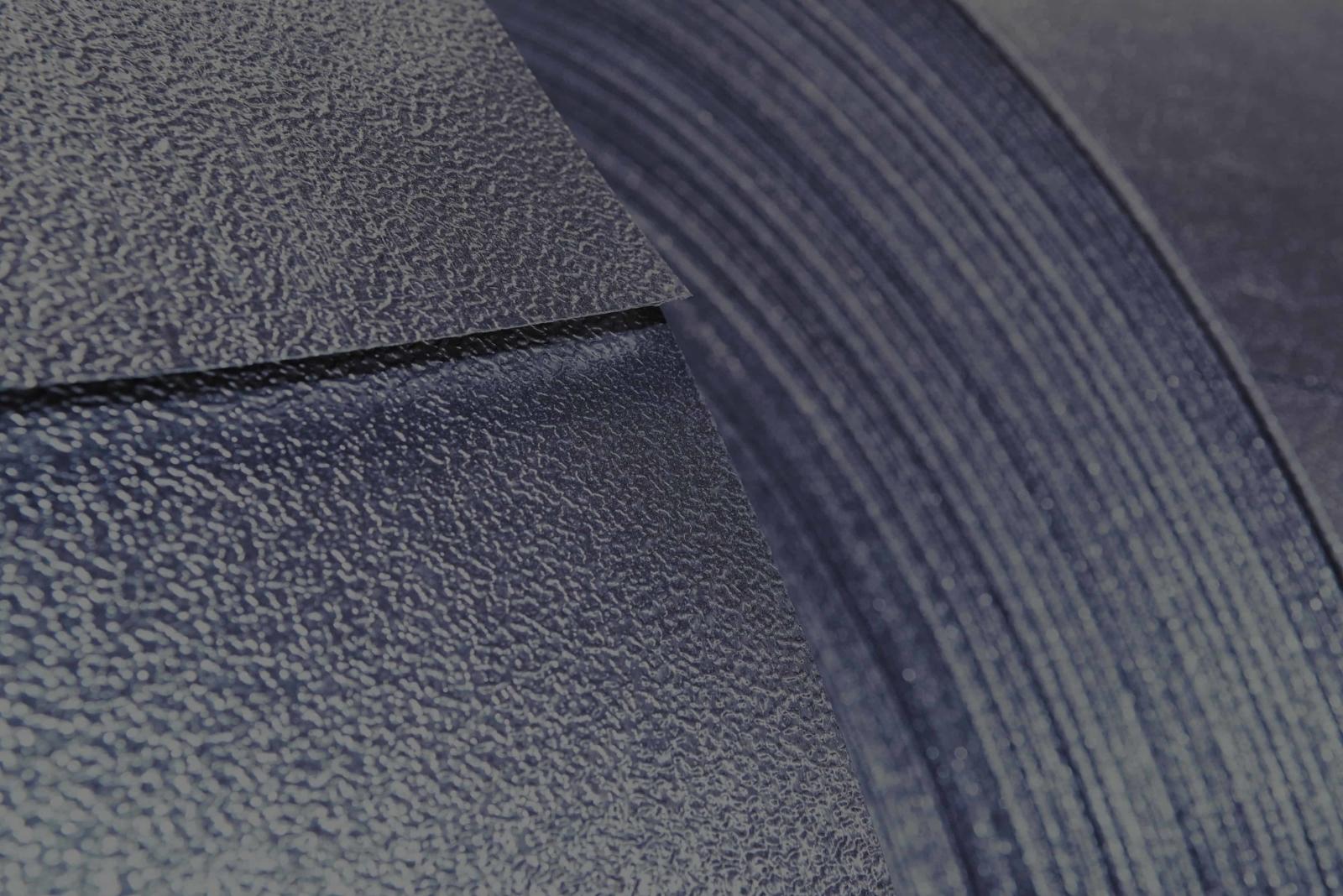

Aluminium Sheet

We live in what could be called the aluminum age, for it is the most commonly used metal in our daily lives, and is all around us in the cars we drive, the planes we fly in, the cans of soda we drink. Aluminum products are in all facets of our lives. There would be no space program without aluminum, which forms the major components of the International Space Station and space shuttle.

One of the advantages of aluminum is that it is 100 percent recyclable. All the various products made of aluminum can be melted down and reused to make more products, which when their usefulness is over can in their turn be recycled. From the soda can to the car engine, aluminum is a reusable resource.

Aluminium, with its outstanding eco-friendly characteristics of light-weight durability, everlasting strength, high heat reflectivity and low thermal emissivity, makes it the ideal material for roofing sheets. See how ALCOM’s products can help in your next project.

As one of the leading rolled products producer in Malaysia, ALCOM supply a wide range of coil and sheet for general engineering, architectural, construction and manufacturing industries. Our coil, sheet and plate are characteristically tailor-made to suit customers’ preference.