The Durability of Aluminium Sheets

In the 1970’s, there was a large-scale movement for beverage companies to stop using steel cans for soda pop and beer. Their existed the need to switch to an alternative material that offered lower cost in production, thus the aluminium can was born. Aluminium weighed less, cost less and recyclable, so beverage companies were on board very quickly and the change became permanent. Today, aluminium, especially aluminium sheets, is used for more industrial applications than ever before.

As a low-cost material that is both tough and lightweight, aluminium sheets has been used across many industries for a number of years. In contrast to steel, aluminium weighs less than steel. Aluminium is cheaper to manufacture, and easier to bend into a variety of shapes. It can be shipped easily (less weight=less cost), and makes many items lighter in weight (cars, airplanes, etc.). Aluminium is also stronger and weighs less than tin, making aluminium a more cost feasible product.

Grades and Thickness

The sheeting is available in a variety of grades. Each grade is manufactured with specific designated usages. Certain grades contain a combination of alloys to reinforce strength and/or chemical resistance; while other grades are heat-treated structurally, in order to maintain its resistance to corrosion. Commercially pure aluminium sheets is generally regarded as the most chemically and weather resistant, but is not as strong as aluminium alloy grades.

Aluminium sheets also comes in different thicknesses. In the manufacturing process, pre-treated aluminum ingots are passed through heavy rolls under massive amounts of pressure. The more pressure that is applied, the thinner and longer the aluminum becomes. Aluminum ingots can pass through many series of rollers to achieve their required gage, or thickness. Aluminum sheeting of any grade or alloy can extend from 0.006 inches to 0.080 inches thick. Any gage that is thinner than a gage of 0.006 is considered to be aluminum foil; whereas anything thicker than 0.080 is considered to be a metal plate.

Malleability

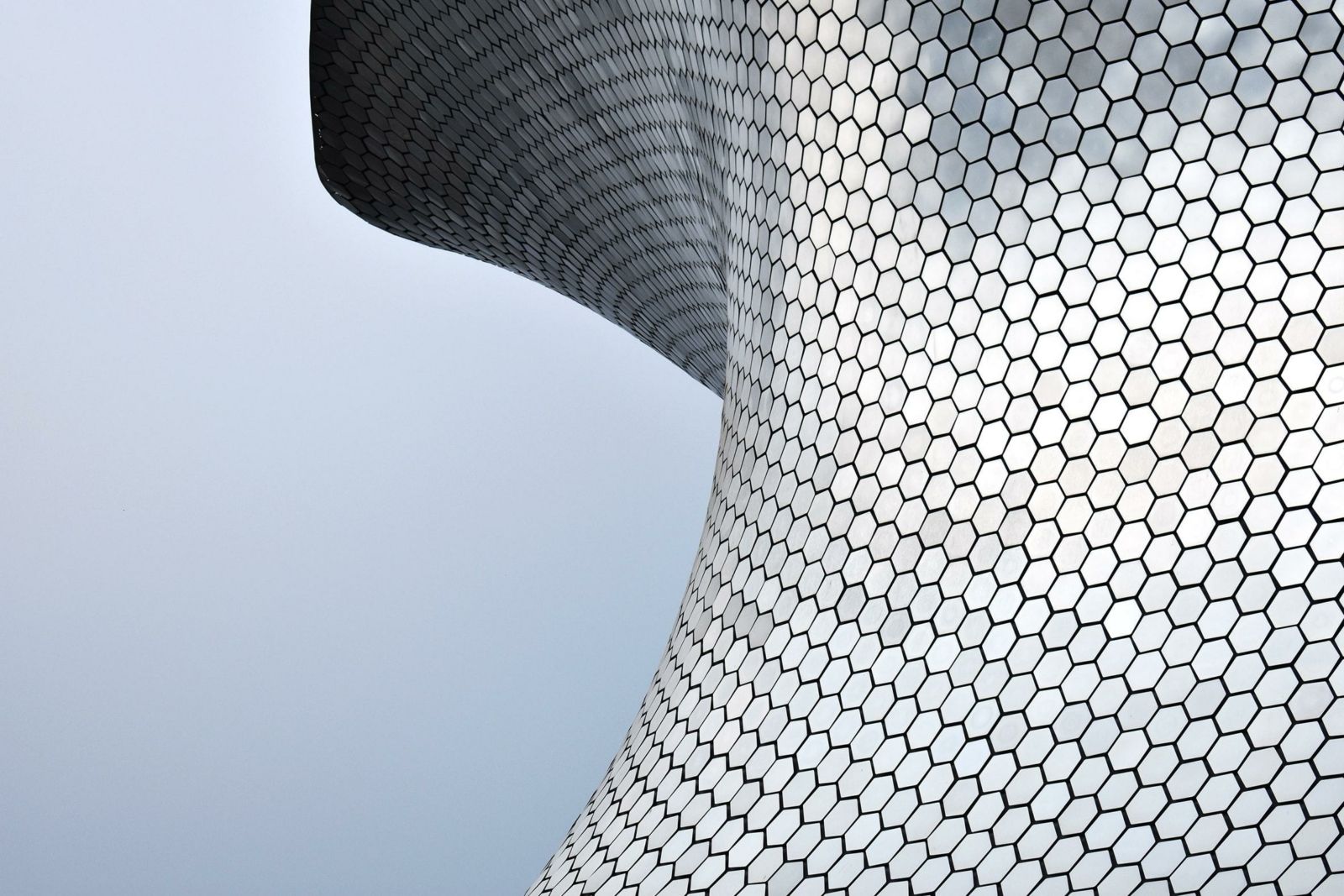

Aside from being able to manufacture aluminium sheets in a wide array of grades and gauges, aluminium is a substance that can be formed, molded, stamped and anodized to just about any color in the rainbow. Assorted finishes are also possible – matte, glossy, and even a number of textures can be etched into aluminium sheets to create a unique appearance. With aluminum’s low cost and high malleability, it is perfect for household appliances such as toys, signage and machinery.

There are other uses, ranging from packaging, to the automobile and aerospace industries, to construction. Aluminum cans used in consumer markets are durable, hold up against corrosion, and are inexpensive to produce. Automakers use aluminum sheeting for paneling on cars, trailers, and on semi-trucks. Those in the aerospace industry construct planes and other equipment from aluminum sheeting due to the cost effectiveness and strength, yet it weighs less than other similar products. In construction, aluminum sheeting is used for building exteriors (aluminum gutters and siding) as well as structural interiors (duct work).

A naturally-abundant element found throughout the world, aluminum is an ideal material for an extensive range of purposes. Its lightweight, hard-wearing durability rivals steel and tin. It provides resistance against weather and is not corrosive. It can be produced relatively simply and at a lower cost, and offers ease-of-use on a manufacturing level. Aluminum is available in many different grades and gages; making it suitable for every application imaginable.

By C. Meyman

ALCOM, the largest manufacturer of rolled aluminium products in Malaysia and a leading supplier in the Asia Pacific region, offer wide range of aluminium products.