Aluminium Fabrication Is All Around You

Do you ever wonder where things come from? If you don’t, you should! Most of the things in your daily life could be the result of aluminium fabrication.

For years, aluminium has been recognized as a reliable and versatile material, when it comes to the aluminium fabrication of everything from simple architectural products to complex machinery. Industries such as architectural, marine, and hydro-electric industries rely on aluminium fabricated products.

The Benefits of Aluminum

Aluminum fabrication takes advantage of aluminium in many ways. It is making the material a go-to resource for a virtually unlimited number of applications. Some of these benefits include 100% recyclable, naturally resistant to corrosion and non-magnetic.

Aluminium also offer benefits from easy component joining, virtually seamless and has wide range of finishing options. Besides, aluminium is resilient, highly reflective and can be polished to a bright finish.

Furthermore, aluminium increase in strength as temperature decreases. It also features high electrical and thermal conductivity.

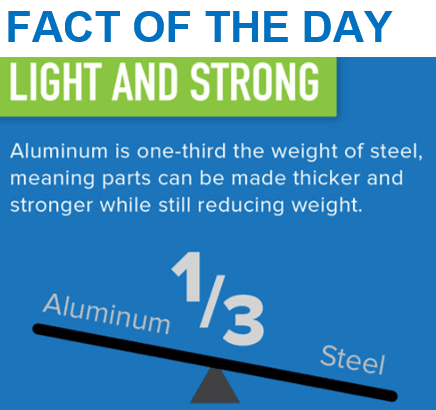

Aluminium is one third the weight of steel, therefore has low tooling costs. With aluminum fabricating, complex shapes and patterns are not a problem. Moreover, aluminium is less labor intensive than other metals. It is allowing for greater cost efficiency.

But What is Aluminum Fabrication?

Fabrication is the construction of something from raw materials. However, that “something” could be a simple metal sign or a precision cut turbine blade. When it comes down to it, aluminum fabrication is not only a precise and scientific process. It’s also an art, used for much more than “products”. Aluminum fabrication can involve:

Fine Plasma Cutting: For aluminum fabrication, fine plasma cutting offers high precision, low lead times, and sharper edges.

Laser Cutting: Laser cut aluminum fabrications enable the fabrication of complex parts that require ultra precise cutting. While still ensuring fast lead times and cost efficiency.

CNC Machining: CNC machining is technology used to produce close tolerances and better fabrications with accurate computerized machining.

Forming: Metal forming includes bending, rolling, and turning, to reliably shape aluminum fabricated components into all shapes and sizes.

Welding: Welding for aluminum fabrications combines tried and true welding technology with the latest modern innovations.

As you can see, aluminum fabrication can involve quite a bit. But it’s good to know how the many things you interact with every day are made. Look around, wherever you go. What can you see right now that could be the result of aluminum fabrication? The railings outside? The metal installations at your local museum? The building you’re working in?

s one of the leading rolled products producer in Malaysia, Alcom supplies a wide range of coil and sheet for general engineering, architectural, construction and manufacturing industries. Our coil, sheet and plate are characteristically tailor-made to suit customers’ preference.