Products Overview

Aluminium is a lightweight, strong, and flexible metal. Due to its unique properties including durability, impermeability, high thermal and electric conductivity, resistance to corrosion and 100% recyclability, aluminium is found in an enormous amount of products. In terms of consumption growth, aluminium has long outpaced steel, copper, and zinc. With our advanced technology and manufacturing leadership, we transform aluminium into a material advantage for our customers in key markets throughout the world.

Our Facilities

ALCOM Sheet & Foil

We at ALCOM are equipped with capability to produce 36000mt per annum of hot band production output from three state of art continuous casting. Our rolling facilities comprises of 4-high cold mill and 4-high foil finishing mill. We have 6 sheet annealers and 10 single annealers.

ALCOM Nikkei Specialty Coating

Alcom Nikkei Specialty Coatings Sdn Bhd (ANSC) is ALCOM’s wholly owned subsidiary which was incorporated in 1991 as the first plant outside of Japan to produce pre-coated finstock with Japanese technology supported by Nippon Light Metal Co. Ltd. (NLM) of Japan. It possesses state of the art coating fin technology and is today a major supplier of coated fin stock to many of the Japanese transplants in this region.

Our Core Products

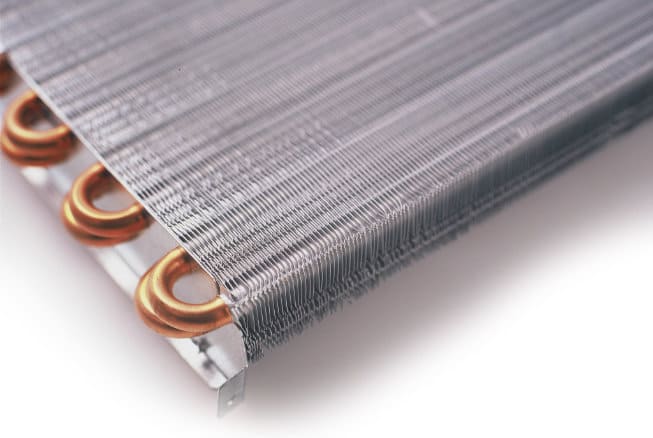

Fin Stock

Bare Fin / Coated Fin

ALCOM is the leading global provider of premium aluminium fin stock materials for the air conditioning industries, and aluminium roofing and cladding for the building trade industry. Aluminium is ideal for heat exchange because it conducts heat extremely well, is lightweight, corrosion-resistant, and can be recycled easily.

Specialty Products

Coiled Sheets / Thread Plate / Stucco Embossed Coil Sheets / Cap Stock / Narrow-Width Coil / Flat Sheets

As one of the leading rolled products producer in Malaysia, we supply a wide range of coil and sheet for general engineering, architectural, construction and manufacturing industries. Our coil, sheet and plate are characteristically tailor-made to suit customers’ preference.

LIGHTWEIGHT

Aluminium is a very light metal with a specific weight of 2.7 g/cm3, about a third that of steel. For example, the use of aluminium in vehicles reduces dead-weight and energy consumption while increasing load capacity. Its strength can be adapted to the application required by modifying the composition of its alloys.

CORROSION RESISTANCE

Aluminium naturally generates a protective oxide coating and is highly corrosion resistant. Different types of surface treatment such as anodising, painting or lacquering can further improve this property. It is particularly useful for applications where protection and conservation are required.

ELECTRICAL AND THERMAL CONDUCTIVITY

Aluminium is an excellent heat and electricity conductor and in relation to its weight is almost twice as good a conductor as copper. This has made aluminium the most commonly used material in major power transmission lines.

REFLECTIVITY

Aluminium is a good reflector of visible light as well as heat, and that together with its low weight, makes it an ideal material for reflectors in, for example, light fittings or rescue blankets.

DUCTILITY

Aluminium is ductile and has a low melting point and density. In a molten condition it can be processed in a number of ways. Its ductility allows products of aluminium to be basically formed close to the end of the product’s design.

IMPERMEABLE AND ODOURLESS

Aluminium foil is completely impermeable and lets neither light aroma nor taste substances out. Moreover, the metal itself is non-toxic and releases no aroma or taste substances which makes it ideal for packaging sensitive products such as food or pharmaceuticals.